Projekthintergrund

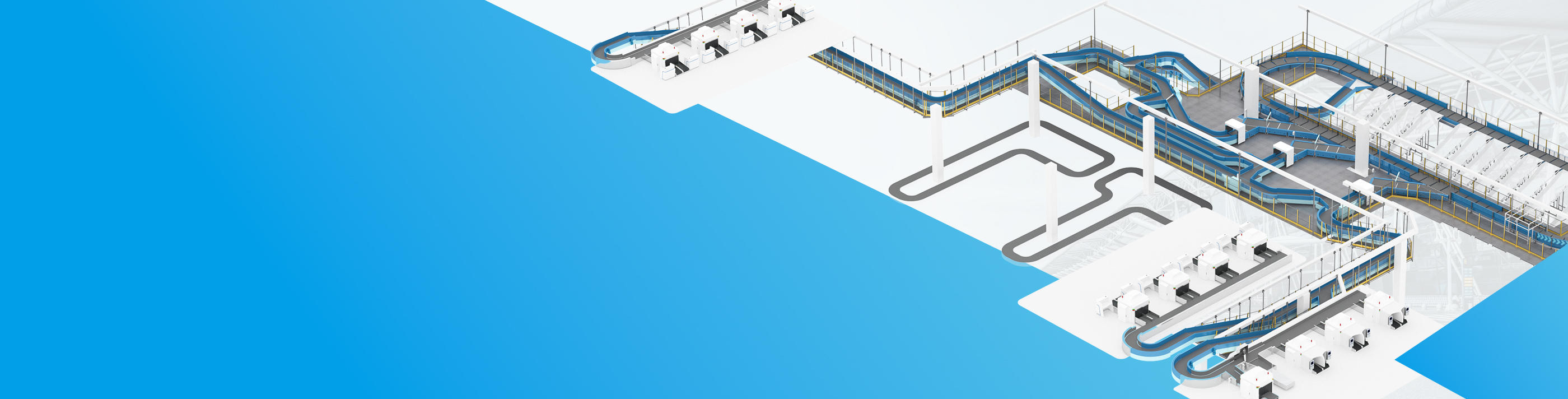

Terminal area: 46,500 ㎡ Designed annual passenger throughput: 5 million pax Annual aircraft movements: 45,000 As an international airport, it serves as a key gateway for the opening-up of the Central China region and an important platform for developing an export-oriented economy. The project began construction in 2022 and has been officially operational. It is the first project in mainland China to adopt a Loop Cross Belt Sorter for fully automated baggage handling. The system's designed capacity for annual passenger throughput and aircraft movements are fully capable of meeting the airport's automated baggage handling requirements during peak periods.

Kontaktieren Sie uns

2,000 pph

System processing capacity

5 million pax

Annual passenger throughput

45,000

Annual aircraft movements

Schmerzpunkte für Kunden

01

Low story height

The customer′s storage space is limited. With the increase in business volume, the problem of inventory backlog is more and more serious, which leads to an increase in storage costs. Therefore, it is urgent to introduce an AS/RS to realize more efficient inventory turnover and flexible storage layout and reduce space waste.

02

Heavy sorting pressure

The airport has an annual passenger throughput of over one million. During peak sorting periods, the airport sorting center cannot meet the demand through manual sorting.

Lösung

The solution adopts a loop cross belt sorting model, with a designed annual passenger throughput of 5 million and an annual aircraft movement volume of 45,000. It consists of three main components: the departure baggage system, arrival baggage system, and control system.

The departure system includes the standard baggage departure system, oversized baggage departure system, loop cross belt sorting system, and baggage tag camera-based recognition system. The arrival system comprises multiple horizontal baggage claim carousels. Supported by integrated software control systems, the solution overcomes the site’s limited sorting space, ensures high compatibility with the existing layout, and enables highly efficient automated baggage handling.

Produktkonfiguration

Standard check-in counter × 28

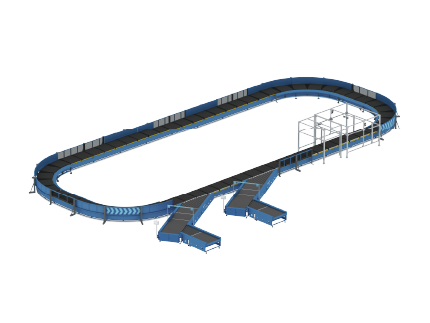

Loop Cross Belt Sorter × 1

Guide conveyor × 3

Sorting terminal chute × 12

Sorting carousel × 1

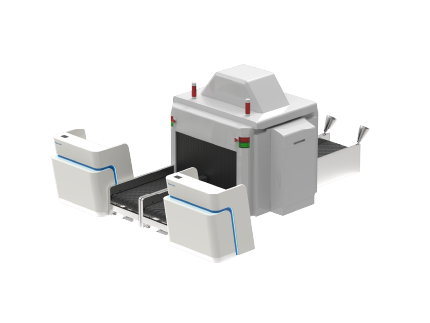

Camera recognition system × 1

Total equipment length: 900 m

Vorteile der Lösung

01

Efficient sorting

The Loop Cross Belt Sorter uses sorting carriers to induct baggage and forms a loop sorting mode, with a system processing capacity 2,000 pph.

02

Precise control

The sorting carrier uses a sine wave servo drive for motorized rollers, achieving the precise control of the running speed and distance of the motorized rollers. The error rate is controlled within 1%.

03

Flexible sorting

The sorting carriers actively output baggage through friction belt operation and the height difference between the carriers and the sorting receiving points is small, sorting baggage flexibly.

Gemeinsam in Richtung Morgen

Kontaktieren Sie uns

Systemkonfiguration

Weitere Fälle

Unsere Partner