In recent years, with the continuous development of the pharmaceutical industry and the expansion of the pharmaceutical market, conventional pharmaceutical logistics models are gradually becoming inadequate. Problems such as multiple circulation stages, long delivery time, high operating costs, and significant storage safety risks have emerged. Against this backdrop, third-party pharmaceutical logistics has come to help.

The customer is a national third-party pharmaceutical logistics company based in Chengdu. The company not only provides third-party storage, transportation, and technology services for the upstream and downstream of the pharmaceutical supply chain nationwide but also acts as a bridge for collaboration and communication between suppliers, manufacturers, and retailers. Building a modernized pharmaceutical storage and management distribution center has become the foundation for the customer to better fulfill this important role.

Deeply understanding the customer’s needs, Wayzim provides a comprehensive intelligent warehousing and logistics solution comprising an automated storage and retrieval system for palletized cargoes, a pallet conveying system, tote attic shelves, a tote conveying and sorting system, and automated conveyor lines.

After fully understanding the customer’s needs, Wayzim designed and built an AS/RS and an attic tote shelf warehouse, focusing on two core goals: improving warehouse utilization and enhancing material flow efficiency.

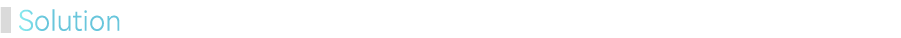

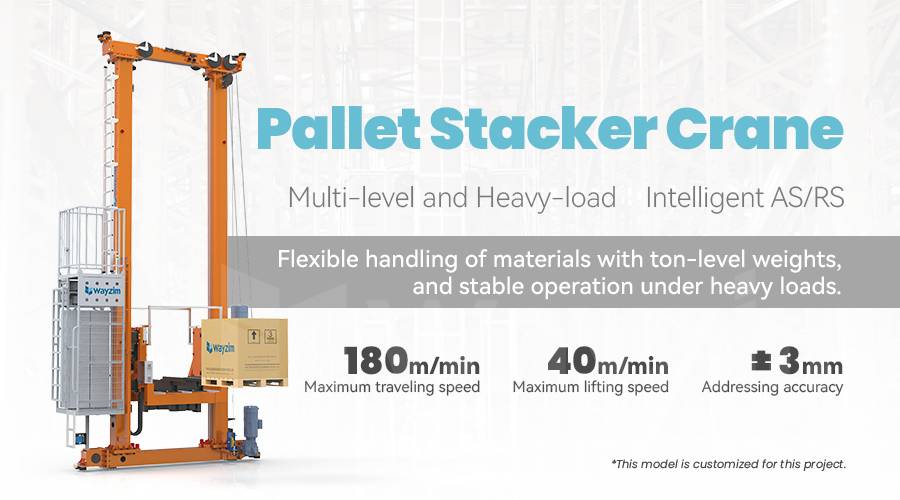

The AS/RS uses Pallet Stacker Cranes as the core, enabling high-density material storage. Together with shuttles and automated conveyor lines, the AS/RS can achieve efficient storage and retrieval.

By fully utilizing the vertical height of the warehouse, this solution resolves challenges including the insufficient storage spaceandlimited inventory turnover rate faced by the customer, and allows the customer to perform efficient destacking and picking within limited space, significantly improving warehouse utilization and operational efficiency.

The attic tote shelf warehouse uses tote discharge points as storage units to store materials of multiple categories. After picking, the goods are sorted and packed quickly through tote conveyor lines and automated sorting conveyor lines. The attic tote shelf warehouse addresses the sorting challenges of a large number of material SKUs and high sorting efficiency requirements and shortens the overall logistics cycle.

The dense pallet storage AS/RS system maximizes the utilization of vertical space in the warehouse and increases storage capacity. The efficient storage mode of combining stacker cranes and two-way shuttles is adopted to realize fast and accurate storage and retrieval of pallets and greatly improve the storage density per unit area.

The tote conveying system is used to transport empty totes and loaded totes between multi-level platforms, which reduces the manual handling distance and the work intensity of operators. This further shortens the picking cycle, speeds up the order processing speed, and improves picking efficiency.

By using the automated information management system, a large amount of goods data is managed by the WCS software system, and the daily inbound and outbound data can be correctly recorded, ensuring the transparency and reliability of pharmaceutical information in the supply chain.

Nowadays, more and more pharmaceutical logistics companies need highly digitalized, intelligent, and integrated logistics solutions to enhance their market competitiveness. Wayzim is committed to advancing the innovation of comprehensive and integrated logistics warehousing solutions, helping customers achieve more efficient, flexible, and sustainable logistics operations. We look forward to collaborating with our customers to drive the transformation of pharmaceutical warehousing and logistics from “accelerating pharmaceutical circulation system reform” to “developing modern green pharmaceutical logistics.”