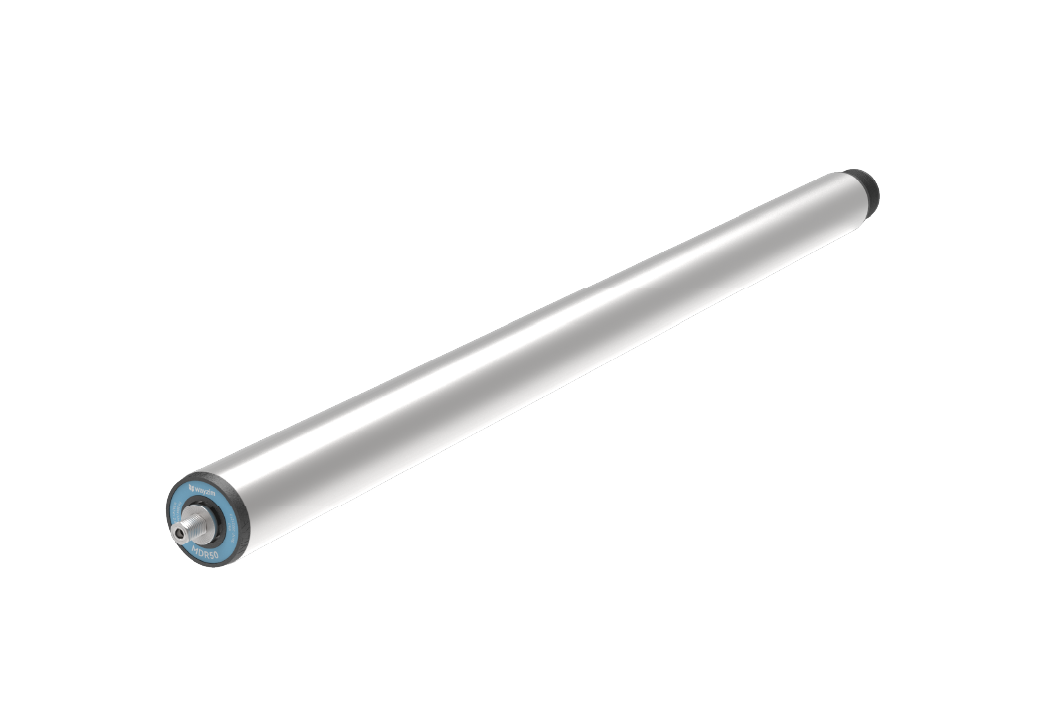

MDR50

Application scenario

System Introduction

The application of the MDR50 Motorized Roller for Intelligent Warehouse Conveyor breaks the limitation of the belt conveyor, meets the continuous batch conveying requirements of materials such as cartons, crates, and goods with pallets, and achieves flexible conveying, matching multi-line conveying scenarios such as straight lines, curves, and diverters/merge units. It is widely used in intelligent warehousing conveying scenarios.

Contact Us

Roller outer diameter

50 mm

Load

0 to 50 kg

Product Display

Competitive Advantage

Solutions

Competitive Advantage

Multiple gear ratios, suitable for diverse scenarios

The gear reducer is equipped with eight different gear ratios, covering a variety of intelligent warehousing and transportation applications. The gear reducer can adjust the output speed and torque based on specific application scenarios, ensuring optimal efficiency under various working conditions.

Simplified assembly process and optimized installation experience

Compared to traditional gear motors, the number of parts required for the drive is reduced, significantly shortening the design cycle and parts procurement and assembly time. The flexible shaft used simplifies the installation process while improving the reliability and durability of the equipment.

Compact structure, environmentally friendly

A compact integrated design is used. The motor and drive are embedded, reducing the risk of oil pollution while saving space. Therefore, the roller is more environmentally friendly. The overall energy efficiency of the motorized roller is also significantly improved, helping customers reduce electricity costs significantly and achieve green production and sustainable development.

TOGETHER TOWARDS TOMORROW

Elevating with High-Tech Solutions

Contact Us

OUR PARTNERS