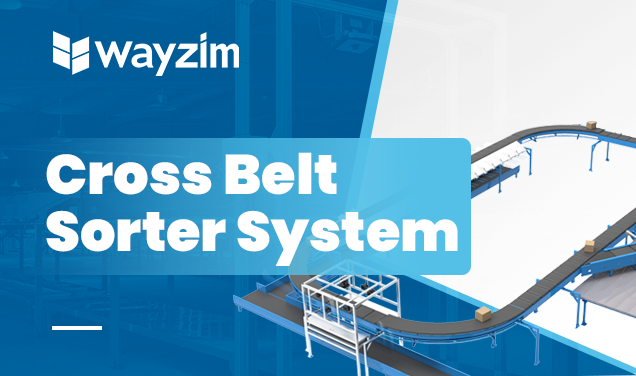

With the continuous increase in parcel volume, the disadvantages of inefficient and error-prone manual sorting of NC parcels are becoming increasingly prominent. An automated solution is urgently required to break the dilemma.

The emergence of the AllType Cross Belt Sorter has overcome the difficulties in automatically sorting NC parcels, such as spherical, elliptical, and polygonal parcels, sorting parcels of all categories efficiently and stably. While effectively improving sorting accuracy and efficiency, the equipment has further reduced labor costs and operational risks for the express delivery industry.

The AllType Cross Belt Sorter is composed of parts such as conveyor belts, manual scanning and infeed stations, sorting carriers, sorting discharge points, and photoelectric belt reset devices. Relying on the double-baffle design and reciprocating bi-directional rotating belts, the sorter supports NC parcel conveying and bi-directional discharge and infeed.

■ Product Functions

● The Industrial All-In-One Cameras are responsible for collecting images and uploading them to the industrial PCs for barcode recognition, display, and counting.

● The Position Detectors inside the infeed station brackets can detect whether there is a parcel on the carrier and determine the parcel position.

● The Position Detectors inside the curved track brackets can reconfirm the parcel position to prevent round parcels from moving due to the curve.

● The carriers are equipped with reset devices.

After a parcel is unloaded, the belt automatically reverses to reset. When the baffle reaches the specified position and triggers the proximity switch, the belt stops reversing and the reset is complete.

● There are two laser ranging sensors on the track behind the discharge point.

If a carrier fails to be reset, it performs a second reset when passing through the sensors to ensure the smooth operation of the sorting process.

Compared to traditional manual sorting of odd-shaped items, the AllType Cross Belt Sorter has the following outstanding advantages in practical use:

01 Baffle structures are added to eliminate the strict requirements on the shape of parcels and help parcels to be conveyed smoothly.

Compared to traditional cross belt sorters, the carriers of the Wayzim AllType Cross Belt Sorter have baffle structures on both sides. The baffles in the direction of carrier movement use fixed baffle edges with anti-fall protective housings, eliminating the strict requirements on the shape of parcels. This allows NC parcels to be conveyed smoothly at a speed of up to 1.5 m/s.

|  |

02 Sorting carriers can achieve automatic discharge in both directions, effectively improving sorting efficiency.

With baffles on both sides, the carriers have a bi-directional discharge function. After a carrier reaches the designated discharge point, the carrier belt rotates and automatically feeds the parcel, greatly improving sorting efficiency.

03 The track is equipped with laser ranging sensors to ensure accurate resets of carriers, raising sorting accuracy.

Two laser ranging sensors are installed on the track behind the discharge point. If the photoelectric sensors detect that a carrier fails to be reset after discharge, the control system starts a second reset when the carrier passes through the laser ranging sensors. This ensures that the carriers are accurately reset after discharge and smoothly start the next sorting task, raising sorting accuracy.

04 The main line uses Wayzim-developed drive motors to effectively reduce energy consumption.

The AllType Cross Belt Sorter uses drive motors independently developed by Wayzim on the main line. The carrier belts are driven by motorized rollers, with precise positioning and high operational efficiency, effectively reducing energy consumption.

05 The modular design allows flexible deployment.

A modular design is used, which can be flexibly and quickly deployed in the solution based on requirements, to meet later needs for elastic expansion.

Currently, the AllType Cross Belt Sorter has passed the factory inspection of top domestic express delivery companies and has been delivered and used in the sites of various top express delivery companies, owning broad application prospects.

With the features of high efficiency, high accuracy, and high flexibility, the AllType Cross Belt Sorter provides an economical and reliable intelligent logistics solution for the express delivery industry. With the promotion and popularization of the sorter, express delivery and e-commerce companies can solve the sorting challenges in their sorting centers, greatly improve operational efficiency, and accelerate intelligent transformation and upgrading.