Project footprint: 89,741.4 ㎡. Daily sorting volume: up to 12M pieces and 3M mail sacks. Located in Yiwu, Zhejiang, this facility processes inbound and outbound mail items for Jinhua, Quzhou, Lishui, and Yiwu, with a daily capacity of 12 million mail items and 3 million parcels. As the company's largest and most automated project in recent years, it features a high-performance, fully integrated intelligent logistics solution from Wayzim that ensures efficient sorting and peak-load management, positioning it among the global leaders in scale and processing capability.

Running speed of the pivot wheel sorter line

Daily sorting volume

Peak processing capacity of the pivot wheel sorting system

Peak processing capacity of the small parcel cross belt sorting system

Economic development has led to a boom in imports and exports. As the increasing volume of express delivery services has put higher requirements on the timeliness and accuracy of logistics services, business operations of the customer are under greater pressure.

Under the continuous pressure of many orders, the sorting center needs to ensure sorting accuracy while maintaining sorting efficiency. Manual sorting only cannot meet the sorting requirements.

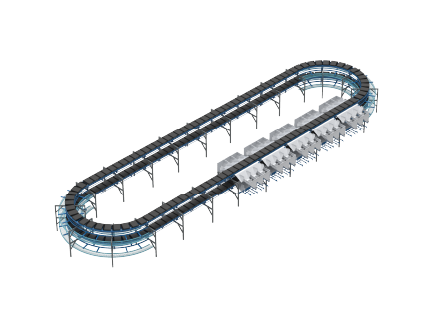

The project integrates automated matrix pivot wheel sorting systems with high-speed sorting systems to enable fully automated processing of all types of mail. Key sections include:

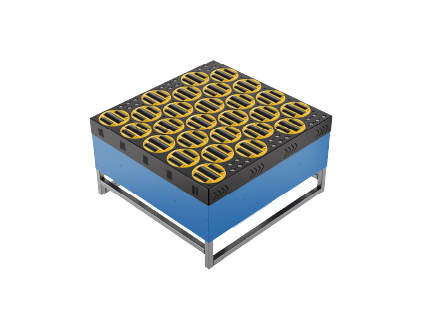

Matrix pivot wheel sorter area for large parcels: equipped with three automated matrix pivot wheel sorting systems, comprising 32 rough sorting lines and 31 fine sorting lines.

Small parcel sorting and parcel collection areas: feature three double-layer cross-belt sorting systems, which innovatively incorporate rope-pull emergency stop switches and locking pull-out baffles to maximize equipment efficiency.

Unloading area: combines “hump” telescoping belt conveyors with incline belt conveyors to merge two unloading lines into one sorting line, significantly improving unloading efficiency.

These multi-functional zones collectively achieve seamless, continuous, and rapid sorting operations throughout the entire process.

Matrix pivot wheel sorting system × 1. The module is used for processing and conveying large outbound express parcels and dispatches.

Double-layer small parcel cross belt sorting system × 2, and matrix pivot wheel sorting system × 1. The module is used for processing small inbound express parcels, and processing and conveying large inbound express parcels and dispatches.

Double-layer small parcel cross belt sorting system × 1, and matrix pivot wheel sorting system × 1. The module is used for processing small special delivery parcels and files, and processing and conveying large special delivery parcels and dispatches.

Processing capacity of the matrix pivot wheel sorting system: 71,500 mail sacks/hour.

Processing capacity of the matrix pivot wheel sorting system: 66,000 mail sacks/hour. Processing capacity of the small parcel cross belt sorting system: 120,000 pph.

Processing capacity of the matrix pivot wheel sorting system: 16,500 mail sacks/hour. Processing capacity of the small parcel cross belt sorting system: 60,000 pph.