Power batteries are the hearts of new energy vehicles, and their safety performance directly affects the reliable operation of the entire vehicle. Each battery component must work together for safety protection, with the battery separator playing a particularly critical role.

The battery separator is located between the positive and negative electrodes to separate the two poles using its insulation properties, preventing short circuits. Separators are polymer materials, requiring nanopores to allow lithium ions to pass through and block active substances to complete batteries' charging and discharging reaction.

The separator quality directly affects the electrochemical properties of a battery such as internal resistance, capacity, and cycle life. Besides, the separator quality has a close relationship with the thermal stability and safety of the battery. Any separator defect can lead to dangerous battery short circuits, thermal runaway, or even fire and explosion. Therefore, strict detection and control of separators is the priority to ensure battery safety.

Wayzim researches the frontier intelligent technology field of machine vision from a forward-looking perspective, and continues to introduce advanced machine learning algorithms such as deep learning algorithms into the machine vision field. Based on this, Wayzim developed the lithium-ion battery separator defect detection equipment. It can detect defects in real time during the high-speed operation of lithium-ion battery separators, protecting the safety of the new energy industry.

Solution

1. Overview

The lithium-ion battery separator detection system of Wayzim can detect defects including pinholes, foreign objects, scratches, oil spots, bright spots, crystal points, black spots, missed coatings, insects, missed spraying, insufficient spraying, over spraying, and droplets. For critical defects like pinholes, the system has achieved a 100% detection rate under the customer's stringent experimental conditions. In addition, this system is not only suitable for the defect detection of lithium-ion battery separators, but can also be applied to the defect detection of optical films, aluminum-plastic films, composite films, and PE films.

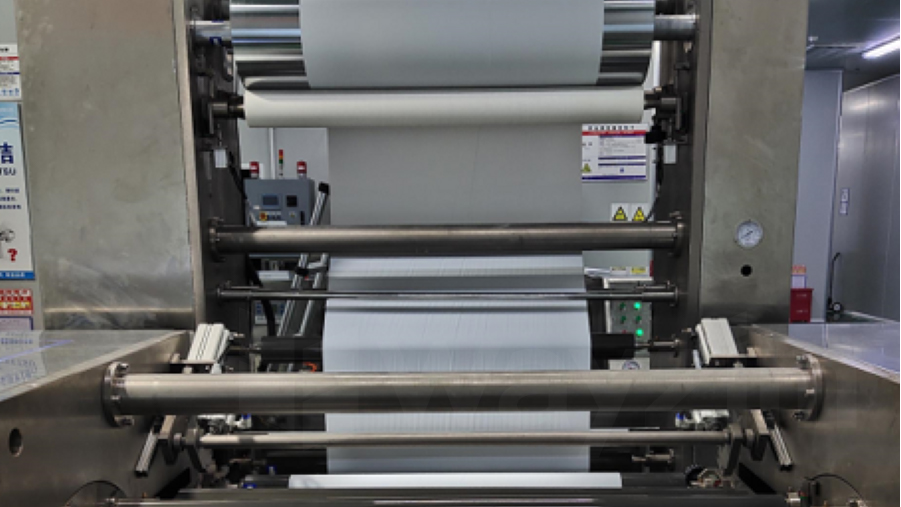

▲ Case Application

2. Detection Process

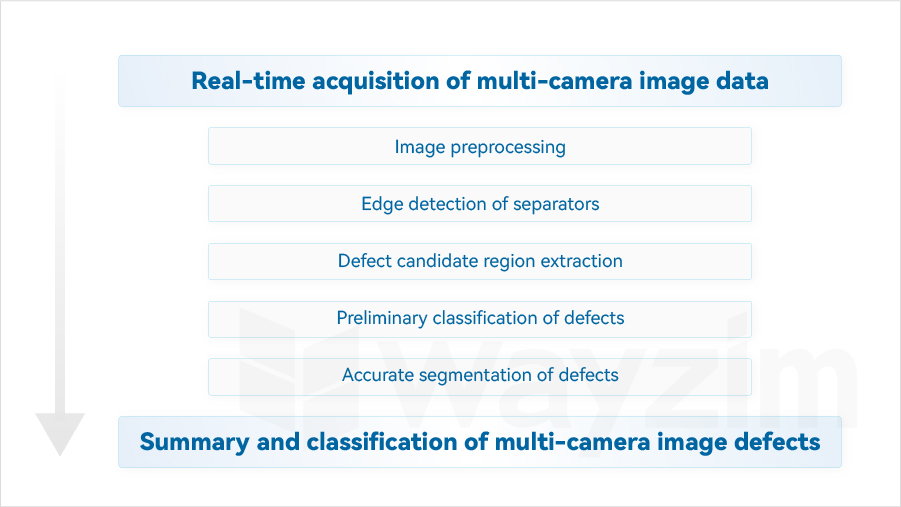

▲ Detection Process

The lithium-ion battery separator detection process of Wayzim can be refined into the following steps:

l Real-time acquisition of camera images. Synchronous processing needs to be carried out among multiple cameras in the system solution. Each camera is independently responsible for the separator images in its field of view, and overlapping areas exist among cameras to ensure the integrity of defects.

l A series of preprocessing operations on the acquired image data. This step is aimed at improving the efficiency and accuracy of subsequent processing. The preprocessing operations include contrast and brightness adjustment, noise removal, and filtering. A separator region is extracted through an edge detection algorithm.

l Defect candidate region extraction. Based on the image data obtained in the previous step, this step identifies and extracts regions where defects may exist.

l Preliminary classification of defects. This step uses a deep neural network to classify defects to determine whether these regions actually indicate defects, and determine possible defect types or categories.

l Accurate segmentation of defects. For the regions preliminarily classified as defects, this step tries to segment them more accurately. The defect segmentation technology based on deep learning can accurately segment the specific shape and size of defects and count the characteristic information of defects. This step involves the application of more complex image processing or machine learning algorithms.

l Summary and classification of multi-camera image defects. In this stage, all defect information is summarized. Besides, further feature extraction and defect classification are carried out as far as possible for subsequent analysis or decision-making. For example, statistical information such as the number and distribution of various defects is calculated.

3. Product Configuration

In the whole detection process, the Wayzim lithium-ion battery separator defect detection process uses computer vision and machine learning technologies to automatically detect lithium-ion battery separator defects. This helps to improve detection efficiency and classification accuracy, thereby reducing the costs of manual detection and the risk of mis-determination. These achievements are inseparable from the strong hardware and software support provided by Wayzim. Wayzim lithium-ion battery separator detection equipment can automatically adapt to separators with different film thicknesses to reduce the formula number, thus greatly facilitating customer use and solving the pain points in the industry.

▲ Hardware Product Matrix

In terms of hardware, Wayzim lithium-ion battery separator detection equipment uses in-house developed vision camera hardware equipped with powerful camera algorithms and related equipment to meet the multiple needs of industrial machine vision such as recognition, positioning, measurement, and detection. The camera with IP65 protection is compact, stable, and reliable, suitable for various harsh visual detection environments.

It is worth mentioning that the detection equipment is equipped with an in-house developed high-speed vision detection system based on an 8K line array image sensor. This system features high definition, high speed, and strong adaptability, making it widely applicable to various complex vision detection tasks on production lines. The application of such a system undoubtedly improves the accuracy and efficiency of defect detection, providing strong technical support for the efficient operation of production lines.

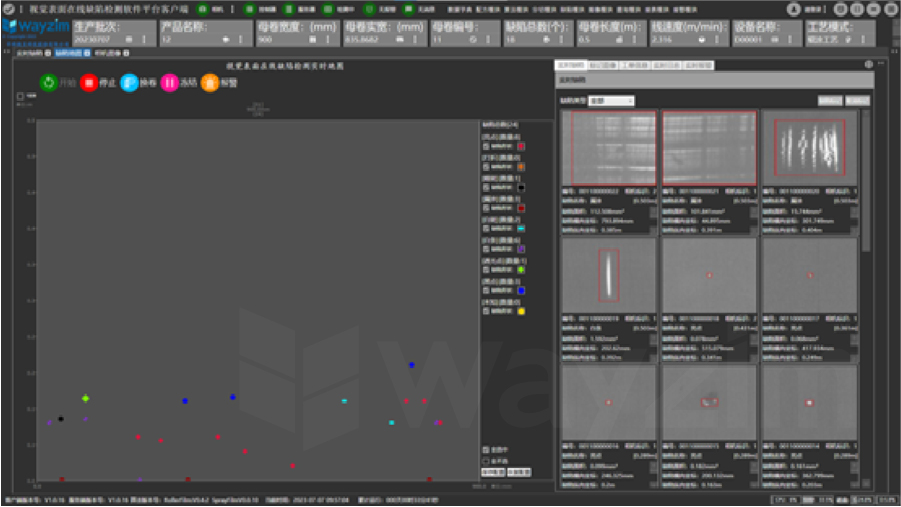

▲ System Software Home Page

The software home page shown in the figure above includes the following functions.

l The software top area displays information related to customer production work orders.

l The middle left area provides operation buttons for system start, stop, roll change, and other functions, linking with the whole set of equipment in real time.

l The lower left area displays the defect map in real time. Different defect types can be displayed in different colors or patterns.

l The lower right area displays defect images in real time. Double-click an image to view the defect details.

In terms of software, the lithium-ion battery separator detection system of Wayzim uses an in-house developed distributed architecture to flexibly expand server computing power to meet the needs of customers for lithium-ion battery separator detection. The system achieves high performance, high reliability, and 24-hour real-time detection.

In addition, the whole software is designed with a high-performance modular framework, which features independent decoupling and strong scalability, maintainability, and flexibility. This enables the software to quickly respond to user customization needs. In terms of operation, the system has a user-friendly interface, easy to operate and convenient to use. Operators can get started quickly with just a short training period.

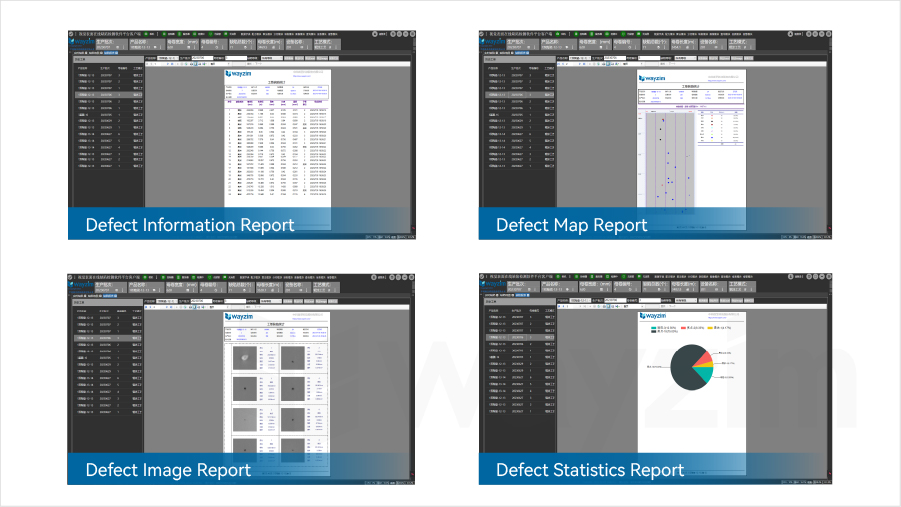

▲ System Software Defect Reports

4. Solution Features

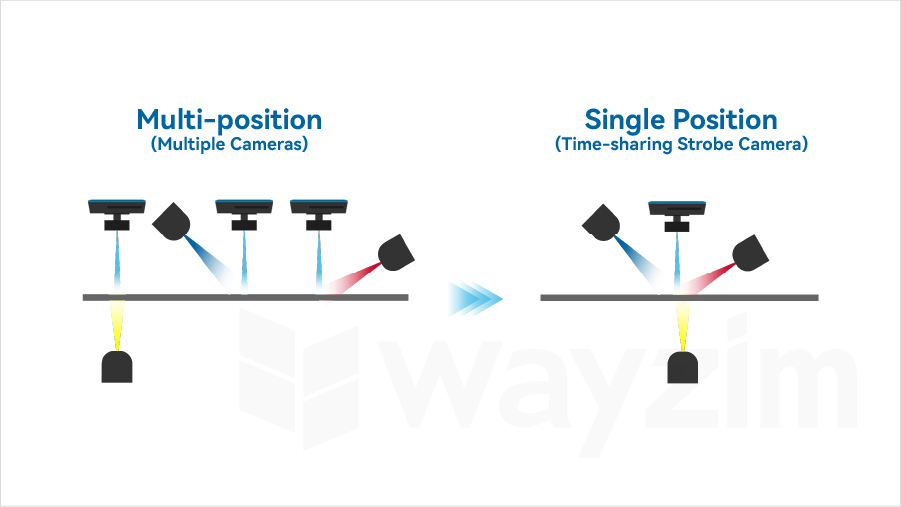

Compared to other similar products, the Wayzim lithium-ion battery separator defect detection equipment has unique technical characteristics. The system uses two solutions: camera time-sharing strobes or light source time-sharing strobes, which can adapt to customer on-site needs.

By precisely controlling the pulse frequency of a light source and synchronizing it with the camera capture time using a high-precision encoder, the camera can capture stable images under high-speed conditions with strobing. Multiple sets of image data with different lighting methods can be collected in the same area at the same time for algorithm fusion detection, enhancing the defect detection rate and classification accuracy. In addition, the detection system uses a professional lighting scheme, allowing the same defect to exhibit different characteristics under varying lighting conditions.

This combination of strobing and lighting helps to distinguish visually similar defects and improve classification effectiveness. Without affecting the customer detection line speed, the combination of strobes and professional lighting significantly improves the classification and detection of similar defects under the same lighting conditions. This not only ensures the detection accuracy but also reduces the risks of mis-determination and missed determination.

▲ Light Source Time-sharing Strobes

In the lithium-ion battery separator detection industry, the Wayzim lithium-ion battery separator defect detection equipment has significant core advantages in the market. One of the core advantages lies in the customized lighting solutions provided to customers using the in-house developed linear light sources and 8K industrial cameras, tailored to the characteristics of different separator materials. The combination of a hardware-based imaging system and in-house developed software image algorithms can accurately detect various defects, and better adapt to different separator materials. This improves detection accuracy and stability, which gives Wayzim a higher competitiveness in the lithium-ion battery separator detection industry by providing customers with higher quality and efficient solutions.

Summary

As a leading machine vision company in the industry, Wayzim always adheres to its corporate mission: Technology innovation and quality craftsmanship. Wayzim provides perfect and integrated solutions to intelligent vision systems, industrial sensors, and intelligent logistics equipment, creating a better future together with customers. In order to achieve this mission, Wayzim continually increases its R&D investment in the machine vision field, focusing on breaking through the core technologies in lithium-ion battery separator detection. Advanced detection methods ensure the safety performance of power batteries, providing strong support for the rapid development of China's new energy vehicle industry.