In recent years, with the continuous increase in the number of parcels, how to improve space utilization and sorting efficiency in limited space has become a pressing issue for large sorting centers and small and medium-sized logistics outlets. The compact Narrow Belt Sorter can be flexibly deployed in various scenarios. It can sort a variety of parcels at the same time, including large items, small items, parcels, and cartons, providing the express delivery industry with a stable and efficient narrow belt sorting solution.

1. Technical Principle

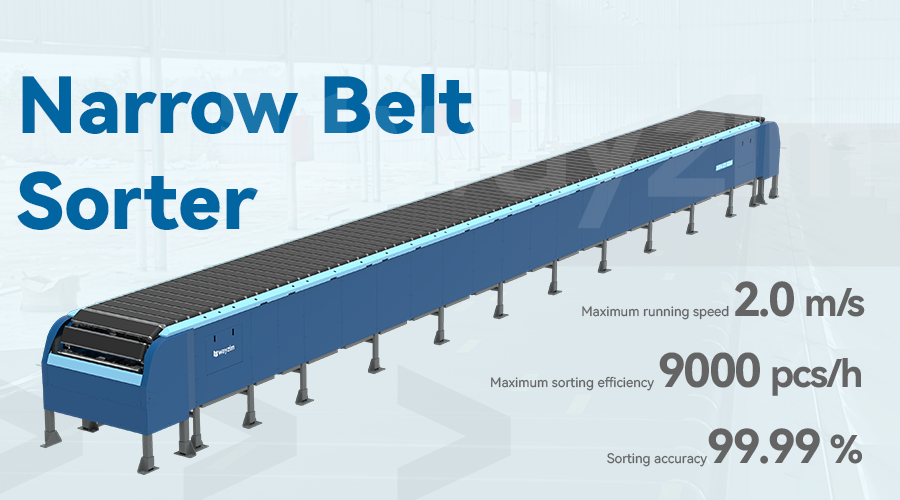

The Narrow Belt Sorter uses carriers that can move bidirectionally as load-bearing and sorting units, which are arranged on a specific drive main line and continuously circulate to sort parcels.

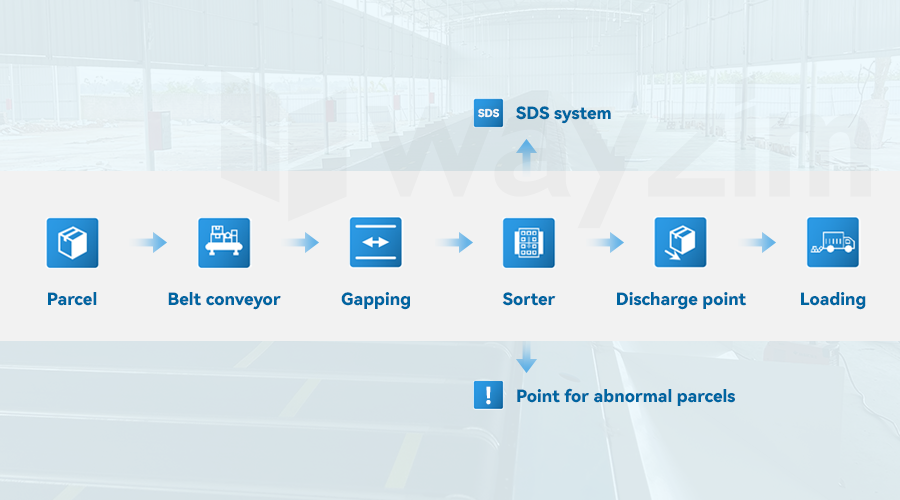

In actual sorting scenarios, the Narrow Belt Sorter forms a narrow belt sorting system with horizontal belt conveyors, incline belt conveyors, induction mechanisms, barcode scanning systems, SDS systems, and chutes. After parcels are placed on the matching conveyor line, the barcode scanning system scans barcode information, the control system of the Narrow Belt Sorter receives and processes sorting signals, and finally, the main line sorting carriers sort the parcels into the corresponding chute for precise sorting, with a sorting accuracy of ≥99.99%.

2. Product Advantages

Wayzim's Narrow Belt Sorter uses stable and reliable infrared communication technology and the proprietary image scanning system, to sort parcels efficiently and precisely. The Narrow Belt Sorter has the following advantages in actual applications.

01 Flexible deployment

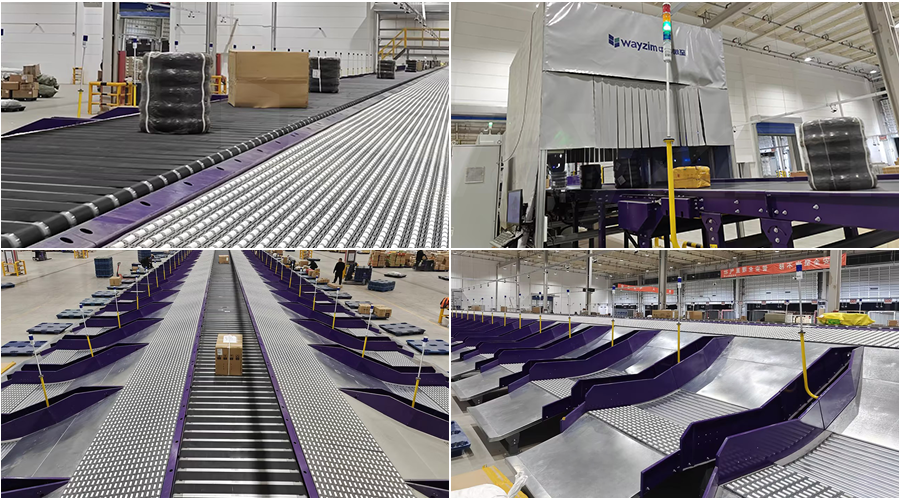

Highly modular design and compact structure for easier maintenance.

02 High space utilization

A vertical circulation structure allows more discharge points in limited space, featuring a higher space utilization rate.

03 Stable and efficient

Driven by a permanent magnet linear motor, carriers are mounted and secured through chain plates and joint bearings to ensure a more stable structure. The maximum running speed is 2.0 m/s, and the maximum sorting efficiency is 9,000 pph.

04 Flexible and stable discharge

The software calculates the precise earlier or later timing for discharging parcels based on the parcel location information provided by the volumetric camera. The carrier speed can be adjusted flexibly as needed to adapt to different main line speeds and multiple types of chutes.

05 Less labor costs

The sorter automatically discharges parcels on both sides, requiring no manual operations and thus greatly reducing labor costs.

3. Product Application

With the flexible deployment and compatibility with parcels of various sizes, the Narrow Belt Sorter has become a mainstream automated logistics sorting equipment. Wayzim tailors narrow belt sorting solutions for customers based on different scenarios. The solutions are particularly suitable for scenarios with high site layout utilization requirements.

In a Narrow Belt Sorter project for a logistics company, we configured two narrow belt sorting lines on account of the long and narrow warehouse, where each narrow belt sorting line is equipped with a 2D Bulk Flow Singulator System and a Large Parcel 6-Sided Barcode Scanning Tunnel.

The 2D Bulk Flow Singulator System separates disordered parcels, so that parcels pass through the Large Parcel 6-Sided Barcode Scanning Tunnel in order at the specified distance. Then, the Large Parcel 6-Sided Barcode Scanning Tunnel accurately identifies parcel information to improve the sorting accuracy for the subsequent Narrow Belt Sorter.

According to the actual sorting needs of the customer, the sorting efficiency of the two narrow belt sorting systems can reach over 9,000 pieces per hour during peak periods, with a sorting success rate of over 99.5% and a return rate lower than 1%. With the support of the narrow belt sorting systems, the distribution center has greatly reduced labor costs while improving sorting efficiency through smooth and efficient automated sorting of parcels in various sizes.

The wide application of Narrow Belt Sorters has improved sorting efficiency and reduced labor costs in the sorting centers and small and medium-sized logistics outlets with limited space, effectively improving the end sorting capacity.

In the future, Wayzim will continue to optimize technologies such as visual recognition and system control, and use more intelligent logistics equipment to facilitate automated sorting in the logistics industry.