The annual 13th China Logistics Technology Summit (LT Summit 2024) was recently held.

This LT Conference advocates "Building Symbiosis In Change", strives to promote the construction of a future-oriented logistics ecosystem, and collaborates with eco-enterprises across the industry and the entire chain to face the opportunities and challenges of high-quality development through co-construction, co-creation and joint efforts.

The award ceremony of the highly esteemed Logistics Technology Award (LT award) was held simultaneously. The award is known as the "Oscars of the logistics industry," renowned for its principles of fairness, impartiality, openness and public welfare, and recognized as one of the most important awards in the logistics field. Wayzim was honored with the Logistics Technology Award 2024 (Innovative Application) for its East China Logistics and Warehousing Center project of China Post.

As the increasing volume of express delivery services has put higher requirements on the timeliness and accuracy of postal logistics services, postal business operations are under greater pressure. Especially for East China, due to its developed economy and booming import and export business, there is an urgent need to address the pressure from the surge in Express Delivery & Special Delivery services through the East China Logistics and Warehousing Center project.

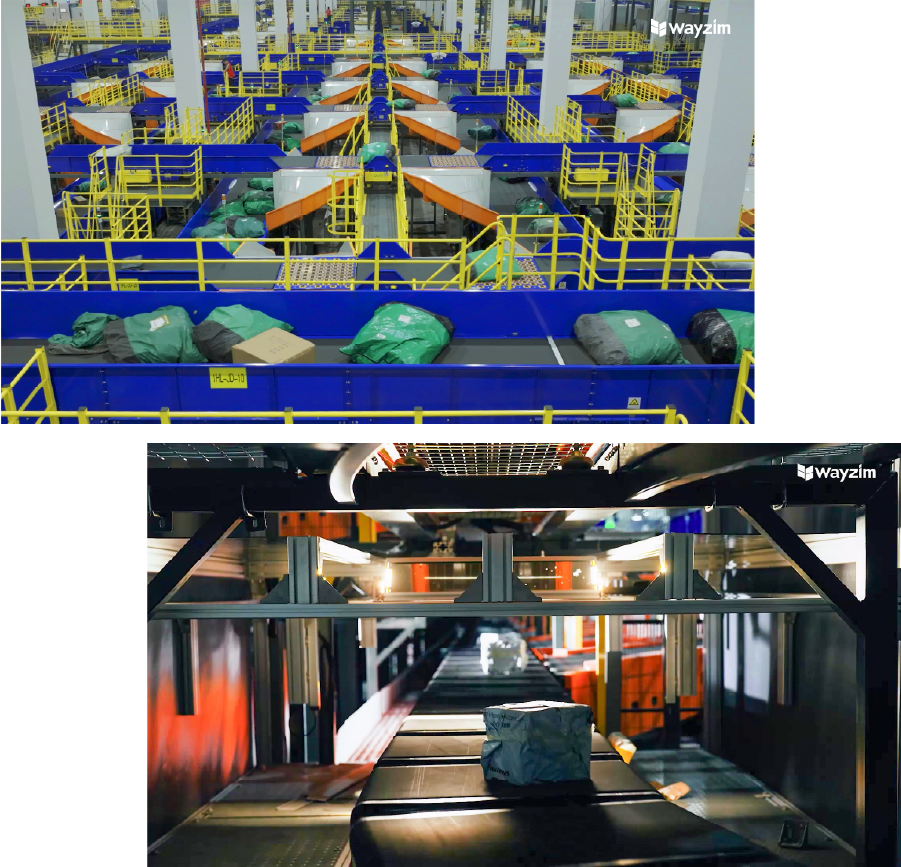

By introducing advanced intelligent logistics equipment and logistics management systems from Wayzim, the East China Logistics and Warehousing Center of China Post achieves automated, IT-based, and intelligent logistics, and promotes its comprehensive service capacity of Express Delivery & Special Delivery. For China Post, this project is a major project with the largest scale, the highest average daily processing capacity, and the highest level of automation and digitalization in recent years.

The East China Logistics and Warehousing Center of China Post, located in Yiwu, the "world supermarket", is mainly responsible for transferring inbound and outbound mail in Jinhua, Quzhou, Lishui, and Yiwu, and some outbound mail in Zhejiang province.

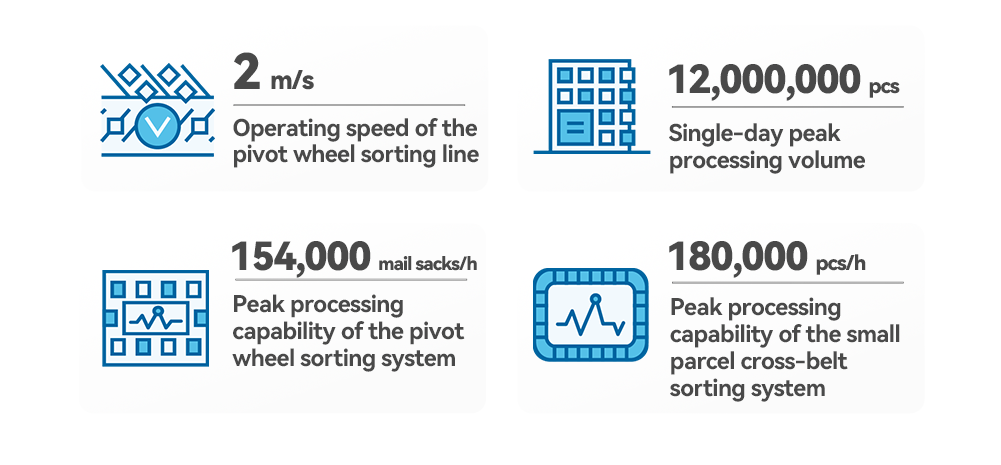

In response to the logistics characteristics of a large number of batches with a small number of items in each batch, Wayzim has planned and implemented an intelligent logistics solution with high performance and high integration to meet the warehousing center's requirements of the increasing volume of express delivery service and high timeliness. The warehousing center's daily throughput reaches 5.1 million items/day. During the Double 11 period, the average daily throughput was 12 million items/day. The warehousing center can easily cope with peak sorting periods.

The process flow of the first phase combines automated matrix pivot wheel sorting systems with high-speed sorters, with mail sacks and large express parcels being directly transferred by the automated matrix pivot wheel sorting systems and small express parcels being quickly sorted by the high-speed sorters. All types of mail can be processed automatically.

The unloading area combines “hump” telescoping belt conveyors with incline belt conveyors to merge two unloading lines into one sorting line, thus effectively improving the unloading efficiency. The picking process uses modular belt conveyors to achieve the balanced flows of lines.

The matrix Pivot Wheel Sorter area for large parcels uses Six-sided Scan Tunnels to achieve full-angle recognition of mail sacks. Meanwhile, the systems use a secondary scanning mode and a special area for unrecognized mail sacks to improve the feeding rate.

The small parcel sorting and parcel collection areas are equipped with multiple solutions for processing small express parcels based on design requirements. Rope pull emergency stop switches and locking pull-out baffles are innovatively used to fully exert equipment efficiency.

The processes, including mail unloading, picking, sorting, loading, delivery, and transportation, are streamlined in a continuous and uninterrupted manner, enabling fast in and out.

Due to advanced process flow and a high degree of automation, there is almost no manual intervention from the entry to the exit of mail.

The shortest duration from unloading to loading for mail sacks and large parcels at the warehousing center is 55 seconds, while the shortest duration from unloading to loading for odd-shaped items and mail requiring sorting on the small parcel sorter is 5 minutes and 21 seconds.

The successful implementation of the project as well as the stable operation of the subsequent automated sorting equipment reduce the damage rate while effectively improving sorting efficiency and accuracy. The timeliness and accuracy of enterprise logistics services are greatly enhanced to alleviate increasing operational pressure.

This award reflects the close cooperation and joint innovation between the Zhejiang branch of China Post Group and Wayzim and proves Wayzim's mature intelligent solutions in the logistics industry and great project delivery capabilities.

In the future, Wayzim will continue to deepen its presence in the logistics field, contributing more wisdom and strength to the prosperity and development of the logistics industry.