E-commerce enterprises carry out big promotions on the “Double 11”, and the flood of parcels arrives as expected.

The volume of e-commerce sales at the front end is soaring, while logistics at the back end is also racing against the clock. On an intelligent sorting “expressway”, the whole process of a parcel from unloading from the truck to the completion of sorting and reloading without landing can be completed in a few minutes.

Many businesses can't help wondering how to make parcel sorting so smooth?

Entering the logistics park, we can see that in the distribution center that has completed the automation upgrade, sorting lines are extended from parcel collection accesses in a line to the factory. At the front end of each sorting line, the “only way” for each batch of parcels is just a DWS manufactured by Wayzim.

Making progress while maintaining stability, without compromise

The number of parcels is soaring with the surge of business orders, and the pressure of logistics sorting goes to the distribution center.

On the one hand, the whole operation process is complicated, and the inaccurate data collection is easy to generate a variety of errors.

On the other hand, some parcels are of irregular shapes, making manual collection difficult. Manual recording of parcel data is time-consuming and laborious, with frequent errors or inaccurate calculations, and when the volume of goods increases, more manpower is needed.

Therefore, the importance of relieving the problems from the front can be imagined. Wayzim’s DWS can complete “volume measurement + weighing + code scanning + photographing + calculation + system docking” in one step, and “stably” solve the problems of difficult volume measurement, poor accuracy and high labor cost of goods.

Wayzim’s DWS is capable to make progress while maintaining stability, without compromise. With the help of smart camera code reading system, Wayzim’s DWS can take photos and identify the top surface and four sides of every parcel, and automatically capture the express sheet number on the parcel; the industry-leading industrial vision technology can meet the strict requirements of dynamic size recognition and adapt to different operation scenarios with intelligence.

Combined with other automatic sorting equipment, Wayzim can help logistics enterprises save labor costs, improve operation efficiency and optimize comprehensive benefits.

Smoothness, high efficiency and reliability

There are always personalized requirements in actual working scenarios. With two weighing sections of single and double scales, Wayzim’s DWS can be customized according to customers' requirements for speed, handling capacity and accuracy.

Among them, the single-scale DWS can handle 2,800 pieces/hour while the double-scale DWS can handle 4,000 pieces/hour (the floating range is 3,300-5,000 pieces/hour according to the proportion of parcels).

After several tests on peak flow of promotions by e-commerce enterprises in Double 11, Wayzim’s DWS can be regarded synonymous with high efficiency and reliability.

Stable output

During the operation, Wayzim’s DWS can automatically capture the parcels in transportation, collect the size information and complete the complete reading of the parcel data.

At the same time, integrating the volume, weight and bar code data information collection systems, Wayzim’s DWS can capture the volume, weight and bar code information in a single operation.

In addition, thanks to the process flow optimization by Wayzim, the process flow can be efficient and stable through rapid measurement and automatic data transmission.

Stability guarantee

In the large-scale application of automatic sorting scenarios, stability is an important indicator of product reliability. Wayzim’s DWS is easy to install and maintain, which is worthy of industry customers' delivery of sorting burden to TA.

With the help of experienced technicians, Wayzim’s DWS can quickly activate and run the system.

Without external movable parts, wear and resulting maintenance costs can be minimized, and there is no fear of challenges in the face of high-intensity working scenarios.

Wayzim’s DWS adopts modular design, which can easily meet the diverse needs of customers with high cost performance. Through system modifications according to the application needs of customers, a DWS with the greatest cost-effectiveness, the highest accuracy and strong functionality can be customized for customers.

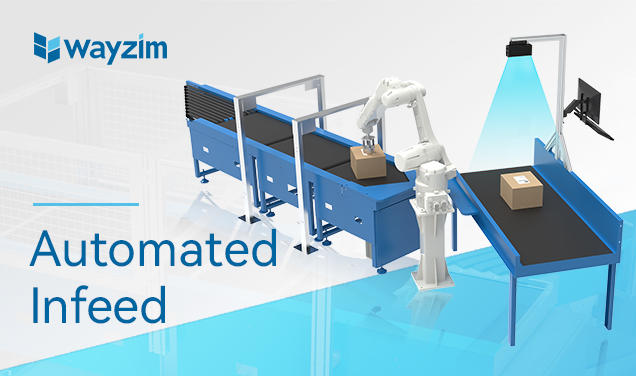

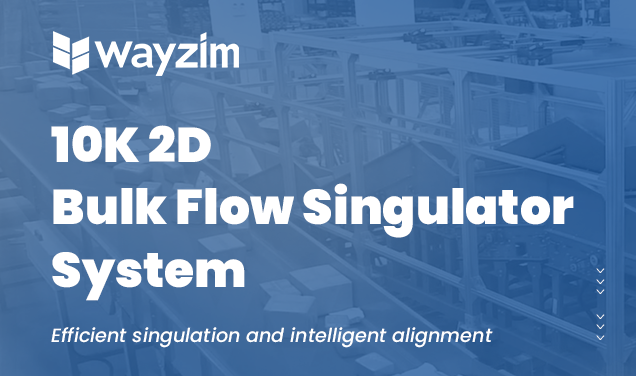

Besides, in the process of technical research of visual products, Wayzim has realized serialized extension and multi-application expansion of core products according to the characteristics of the industry and the development trend of the future downstream application market. For example, 2D/3D visual guidance and positioning system has been widely used in the core components of the stack separation vision system, singulator vision system, arrival/stack detection system, position detection system, automatic parcel infeed vision system, etc., realizing the full automation of the sorting process together with the stack separator, singulator, centralizer and other supporting machines.

The peak of Double Eleven has arrived, and Wayzim has more “coups” to help customers bear the pressure, save operating costs and maximize economic benefits in the logistics test.