In 2022, China’s express delivery volume will once again exceed 100 billion parcels. In the hundreds of millions of parcels transported and sorted every day, the contribution of Wayzim’s intelligent logistics vision systems cannot go unnoticed.

Keep smooth flow and handle various parcels accurately. With the wide application of automatic handling devices, Wayzim’s intelligent logistics vision systems support accurate parcel information processing, which brings continuous improvement to the overall operation efficiency of the industry.

Pains of the Industry

In each express transfer center, no matter how to read the barcodes for tracking or sorting, the following problems will be encountered. For example, during manual handling, the parcels shall be placed in a way to ensure the orientation of the barcodes is fixed, resulting in low operating efficiency and low cargo flow. In addition, some parcels cannot be placed in a way to ensure the orientation of the barcodes is fixed, and such parcels shall be handled separately, which will affect the overall operation efficiency and cargo flow.

DWS multi-sided barcode reading system

Solution introduction:

With different large-resolution camera combinations, Wayzim’s multi-sided barcode reading system has realized stable recognition of top, bottom, left, right, front and rear barcodes, liberating the constraints of parcel placement, while supporting dynamic measurement of parcel volume, to improve the efficiency and reduce the labor.

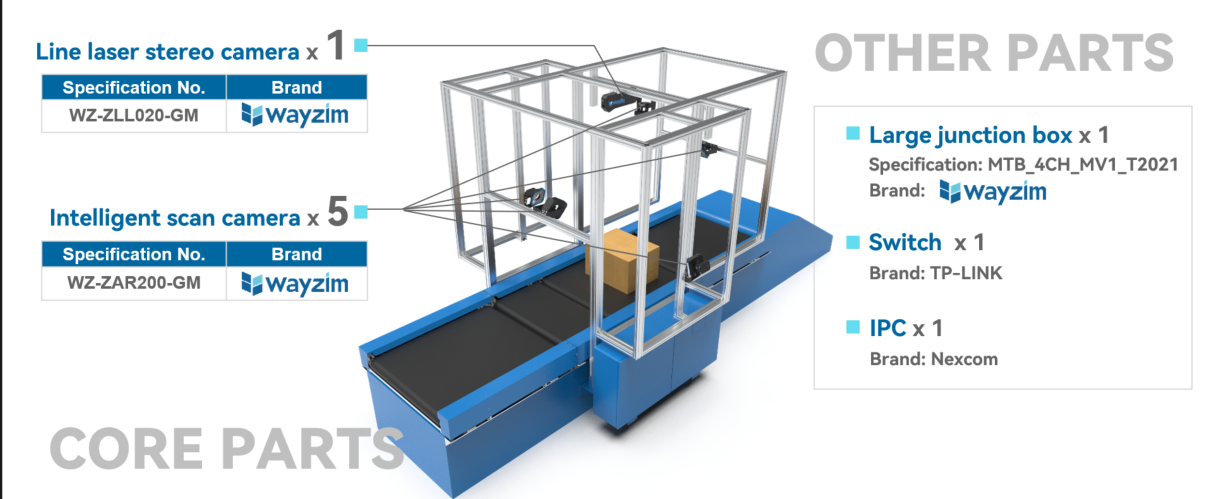

Structure diagram:

Structure Diagram of Wayzim’s DWS

Stand-alone devices:

Wayzim’s area scan camera is highly integrated with LED strobe light source, large depth-of-field industrial lens, high-speed and high-resolution image acquisition components, built-in “horizontal and vertical bidirectional barcode stitching”, “super-resolution reconstruction”, “pixel lossless rotation” and other technologies. It can read all kinds of barcodes at high speed with an accuracy rate of 99.99%. It supports reading of 10 barcodes at a rate of 10 times per second.

Intelligent area scan camera

Wayzim’s light source of industrial scan camera can provide bright LED beads with different color temperatures according to specific needs. The light source lens has two light distribution angles of 40*40° and 60*60°, which can be flexibly matched with beads and lenses according to customer needs. For special occasions where anti-reflection interference is required, the light source can be equipped with a homogenizer to make the lighting in all directions uniform.

Light source of industrial scan camera

Wayzim’s line laser stereo camera uses the principle of triangulation to output the point cloud data, length, width and height data and volume data of the express parcels in real time through the built-in high-precision image processing algorithm and volume measurement algorithm. The camera is equipped with a high-power laser module and a narrow-band filter, which shields visible light interference while greatly improving the dynamic detection range of the device. It is suitable for dynamic volume measurement scenarios such as logistics and warehousing. The measuring speed of this product is not more than 3m/s (± 5mm detection accuracy), and the scan frame rate is 600Hz (1m³ measuring range).

Line laser stereo camera

Solution introduction:

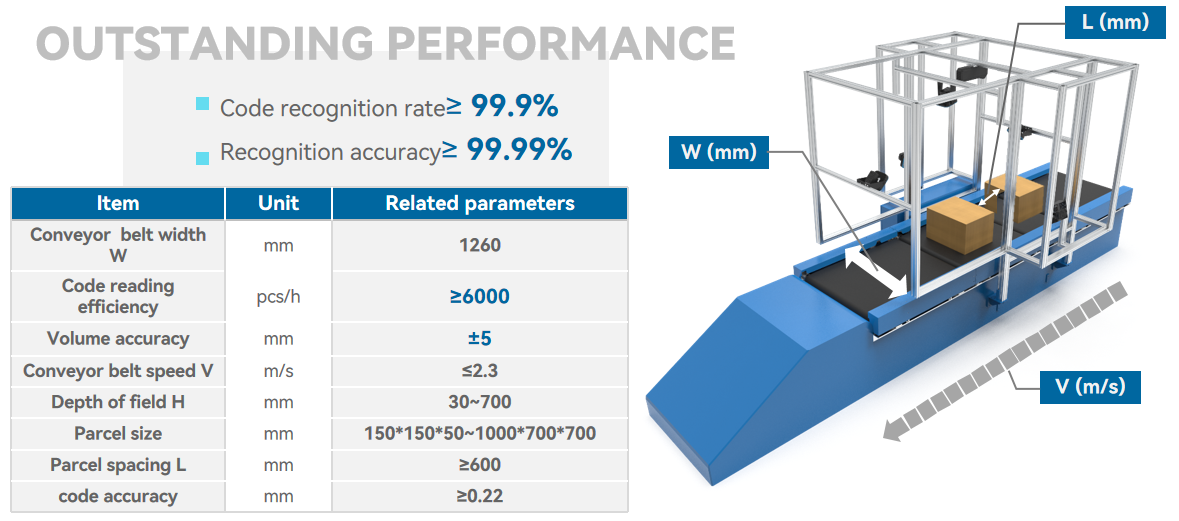

Solution advantages:

1. High accuracy rate: Wayzim’s autonomous algorithm guarantees the speed while reaching 99.9% of the code reading recognition rate and 99.99% of the code reading accuracy rate;

2. Fast recognition speed: During the dynamic transportation of parcels, the intelligent camera is used to complete information collection and barcode recognition, support multiple forms of barcode, and support the belt speed up to 2.3m/s;

3. Rich types: Based on Wayzim’s algorithm platform and the supporting intelligent camera, 128 codes, QR codes, etc. can be recognized at the same time to realize the recognition of multiple parcel types;

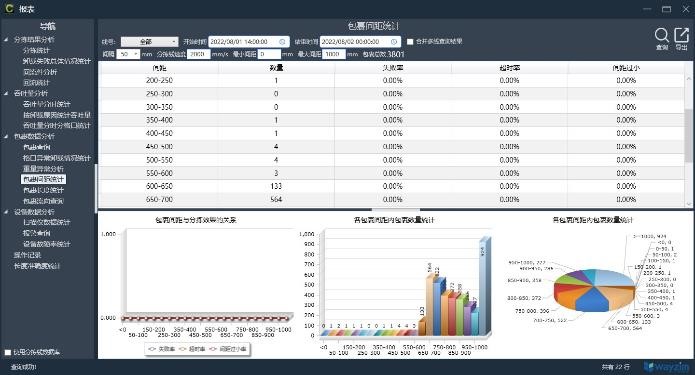

4. Simple operation: The intelligent code reading system can be visualized in the background, with clear data and intelligent operation.

5. Precise volume measurement: Volume measurement technology based on laser triangulation method can dynamically measure the parcel volume.

Visual background processing interface:

Application of DWS Equipment in Integrated Sorting System of ZTO Express

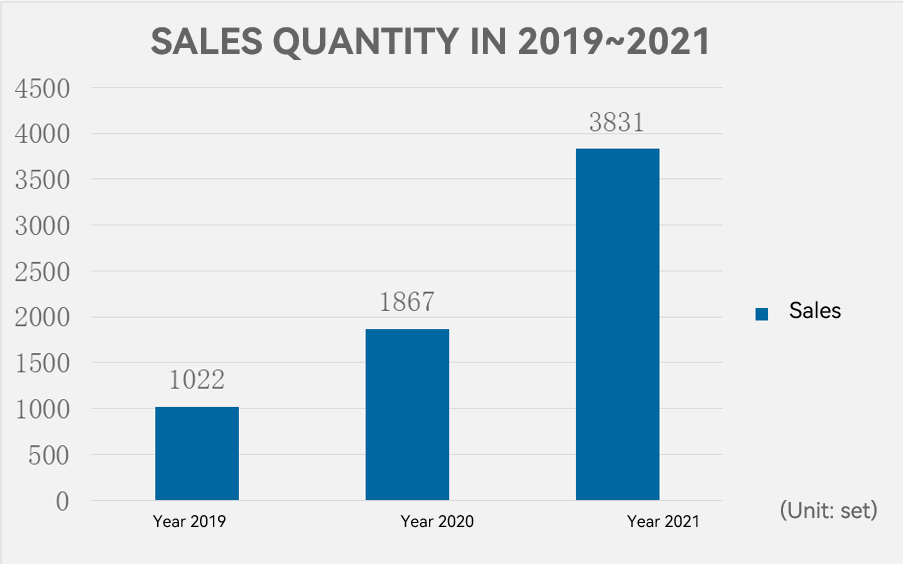

Since its launch in 2019, Wayzim’s DWS equipment has been widely used by many courier services companies, with a cumulative usage of over 7000 sets. In the actual operation test, Wayzim’s DWS equipment has a code reading accuracy up to 99.99%, a recognition rate up to 99.9%, and a volume measurement accuracy of ± 5mm.

From 2019 to 2021, the use of Wayzim’s DWS increased year by year

The express & logistics distribution centers usually shall introduce goods into the sorting process. Wayzim’s DWS is an integrated system to “guard a pass” from the receiving port. At the front end of each sorting line, the DWS equipment takes photos of the top and four sides of the parcel for recognition and automatically grabs the express sheet number on the parcel, to improves the collection volume, up to 6000 pieces/hour, which is greatly improved compared with the single-sided barcode scanning.

For users in the whole logistics & express industry, the advantages of Wayzim’s DWS equipment are also very obvious. Wayzim’s DWS equipment realizes the integration of the camera and light source, which is convenient for optimizing a compact, more stable and reliable layout. At the same time, the camera’s built-in algorithm, coupled with a high-performance hardware acquisition and processing platform, can read various barcodes and 2D codes, and measure the length, width and height of the products.

Next issue:

After receiving the command, the automatic sorter will quickly and accurately classify the goods according to the variety, material, weight and destination of the goods through visual scanning technology, and efficiently transport the goods to the destination.

So, what other intelligent logistics vision products play a role in the automatic sorting process? The next issue will be announced for you!