In the fiercely competitive market of cross-border e-commerce, logistics timeliness is an important indicator affecting consumers’ shopping experience. Timeliness plays an important role in building the brand image and reputation of e-commerce merchants. High timeliness can improve customer satisfaction and market competitiveness. This case depicts the application of Wayzim’s AMR solutions in a well-known cross-border e-commerce platform.

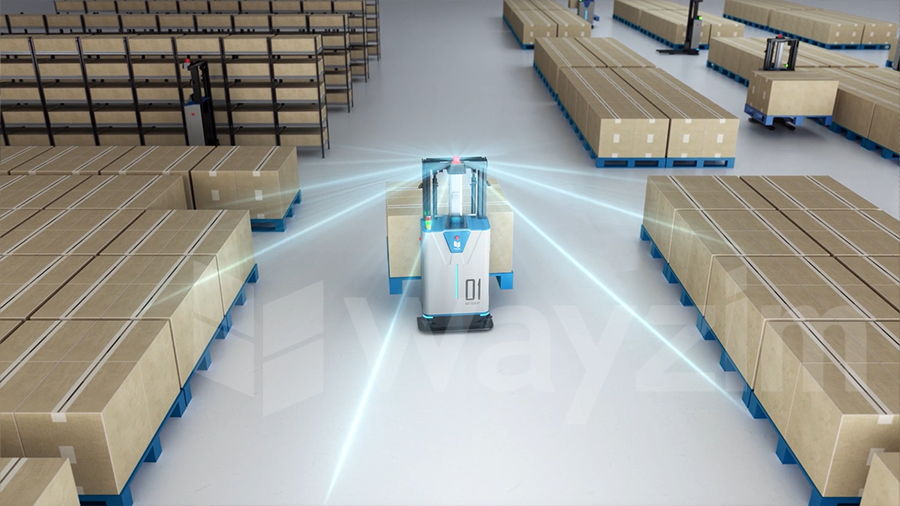

The AMRs independently developed by Wayzim Technology Co., Ltd. (hereinafter referred to as Wayzim) can achieve dynamic obstacle avoidance using laser SLAM and multiple lidars, and dynamically plan the optimal transportation path using advanced autonomous positioning and mapping algorithms. The AMRs can flexibly shuttle through complex environments in a warehouse, and efficiently and accurately transport goods to designated locations, improving the effective material flow inside and outside the warehouses and between production lines.

Project Application

1. Introduction to the Actual Case

In this case, our customer is a company running a well-known cross-border e-commerce platform. The company has warehouses in many countries in Southeast Asia. In the past, the company usually used manual labor and traditional forklifts for long-distance transportation, loading, and unloading. Manual handling usually takes a long time and makes people prone to fatigue or slackness, which may result in accidents. In addition, the installation of long-distance conveyor lines occupies operation areas of warehouses.

Warehouse management is a key factor affecting the logistics timeliness of cross-border e-commerce, and logistics timeliness is one of the important indicators affecting consumers’ shopping experience. In intelligent logistics, robots replace manual handling, which can effectively improve automation and solve the existing pain points in warehouse and logistics management.

Empowered by the rich project experience at home and abroad and the advanced AMR systems, Wayzim helps the customer realize automated handling of logistics in warehouses.

▲ AMR (WZ-FZ2000 Pallet Handling Robot)

2. Operating Process

Based on the working conditions such as on-site environment, goods weight, and vehicle adaptability, this case uses the WZ-FT2000 Pallet Handling Robot. Combined with the "Sky Eye" system and RCS, the robot can realize automated handling, monitoring, and management in the warehouse. Picked goods are moved to the AMR picking area (CB WB Area) manually or by forklift. After the "Sky Eye" system recognizes the goods and the destination storage locations, the RCS automatically generates a handling task and dispatches idle pallet handling robots to transport the goods to the destinations (LEX Area). The entire task process does not require manual issuance of handling tasks, saving time, effort, and worry.

Since the project was put into operation, the customer can query storage location information in real-time through the RCS, and generate reports on inbound and outbound information and handling volumes. This enables the customer to completely abandon the manual counting model and make the handling process informatized and intelligent. In addition, this system allows on-site workers to get rid of the complicated and cumbersome handling processes, thereby reducing safety risks and labor costs.

▲ Operating Process

3. Solution Features

In addition to point-to-point material handling, Wayzim’s AMRs can also realize logistics transportation in multiple interconnected production processes. The application of the AMRs can solve problems such as large logistics volumes and high labor intensity of manual handling in industrial production and warehousing and logistics operations.

The AMRs automatically carry goods to a designated range and store the records, thereby transforming warehouse management from the traditional "people-to-goods" model to the "goods-to-people" model. The AMRs can properly meet the storage and sorting requirements in the cross-border e-commerce industry, and the reliability and stability of the robots make warehouse management more efficient.

■ Performance Features of Wayzim’s AMRs

◆ Laser SLAM Navigation System

The Laser SLAM Navigation system can adapt to highly dynamic environments without setting markers. The system can automatically update the map, with a stable navigation accuracy within 10 mm.

◆ "Sky Eye" System

The "Sky Eye" system can automatically identify types, quantities, and storage status of different storage locations through deep learning algorithms to select optimal picking and placing locations for the AMRs. After receiving pick-and-place tasks, the AMRs can call the real-time storage location data provided by the "Sky Eye" system, quickly locate target picking and placing locations, and accurately perform the handling tasks.

◆Intelligent Scheduling System

Based on an optimized task scheduling algorithm, the robot intelligent scheduling system provides dynamic path planning and optimization for the AMRs to avoid transportation path conflicts, ensure efficient collaboration of multiple AMRs in completing operation tasks, and improve overall work efficiency. In addition, the required number of the AMRs can be dynamically optimized based on real-time operation requirements to achieve optimized management of the AMRs.

■ Advantages of the AMRs Compared with Traditional Handling

◆ Improvement in Automated Warehouse Management

The application of AMRs can improve the level of warehousing automation. Goods can be handled automatically, which makes warehouse management more efficient, avoids errors and omissions caused by manual operation, and improves the accuracy and reliability of warehouse management.

◆ Flexible Transportation

The AMRs can use different transportation methods based on different transportation requirements, making the transportation process more flexible, speedy, and efficient. For example, goods can be transported in multiple modes to achieve efficient transfer among multiple places and departments.

◆ High Work Intensity

The AMRs can automatically enter or exit the loading and unloading stations, workbenches and shelves 24 hours a day to meet the requirements of long working hours and large handling volumes.

◆ Optimized Handling Process

AMRs can optimize the handling process. The AMRs can achieve automated handling, avoid goods loss and damage, and improve efficiency and quality.

◆ Improvement in Safety

The AMRs do not have risks of collisions or accidents during handling. Therefore, the AMRs can reduce personnel risks during handling, such as falls and injuries, allowing employees to complete their work in a safe and reliable environment, thus greatly improving work efficiency.

◆Saving Costs

The AMRs can work 24 hours a day and can replace multiple labor forces in some production processes. This not only greatly reduces labor costs, but also increases work efficiency.

▲ Operating Process

Summary

Strong supply chain systems and logistics services support the rapid growth of cross-border e-commerce. Wayzim has conducted in-depth research in the field of intelligent warehouse management and mastered many key technologies for intelligent warehousing equipment and warehouse management systems.

Therefore, Wayzim can better solve the problems of low level and low efficiency of traditional warehouse management. Wayzim helps cross-border e-commerce companies and logistics giants achieve localized services and timely express delivery overseas, so they can reduce logistics and warehousing costs, improve consumers' shopping experience, and build well-known international brands.